In the field of automated production, truss robots are widely used for handling and palletizing materials and products. Truss robots typically have a large workspace and high precision, and are capable of completing complex operational tasks. In addition, in scenarios such as warehouses, logistics, and loading, the truss manipulator, when combined with material management systems, can achieve automated material management and transportation, improve production efficiency, and reduce labor costs. This article introduces the automatic picking truss robot designed by Truman Company.

Product features

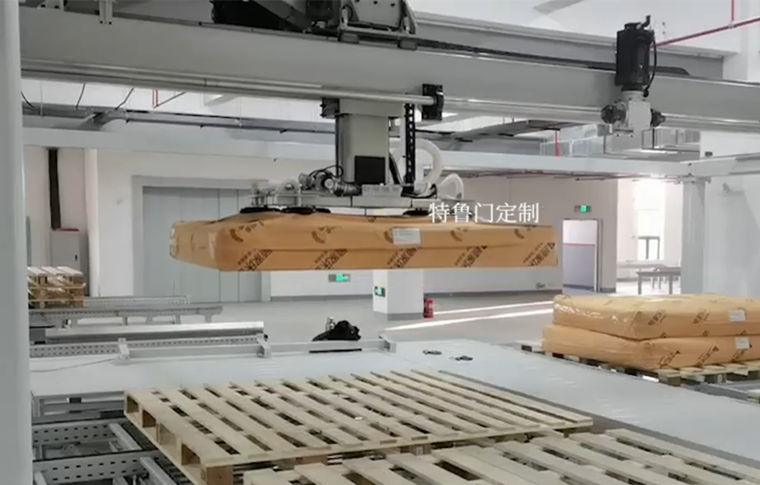

The truss robot is applied in home production workshops to quickly grasp mattress products to designated positions according to system instructions, achieving automatic stacking, palletizing, and unpacking of mattress products. This device operates smoothly, quickly and efficiently, and can achieve automatic handling of large trips, effectively improving mattress picking efficiency and saving labor costs.

Overall plan and layout

The overall plan consists of a structural framework, X-axis components, Y-axis components, Z-axis components, suction cup fixtures, and control cabinets.

working process

Stacking process:

The picking robot moves the fixture to the designated position according to the system instructions, lowers the Z-axis to grab the mattress, and moves the products to the corresponding tray. When approaching the tray, it decelerates in advance and places them in the center position of the tray.

Dismantling process:

After receiving the instruction, the truss robot moves to the corresponding unpacking station, the robotic arm centers to grab the mattress, the fixture moves to the center of the pallet positioning, the fixture descends to grab, and then transports the product to the designated position.

The above is an introduction to the automatic picking robot. This design proposal was developed by Truman Company based on customer needs and actual situations, considering multiple aspects. Truman Company specializes in designing and producing various types of truss robots and has rich project experience. If you have any needs, please feel free to contact us!