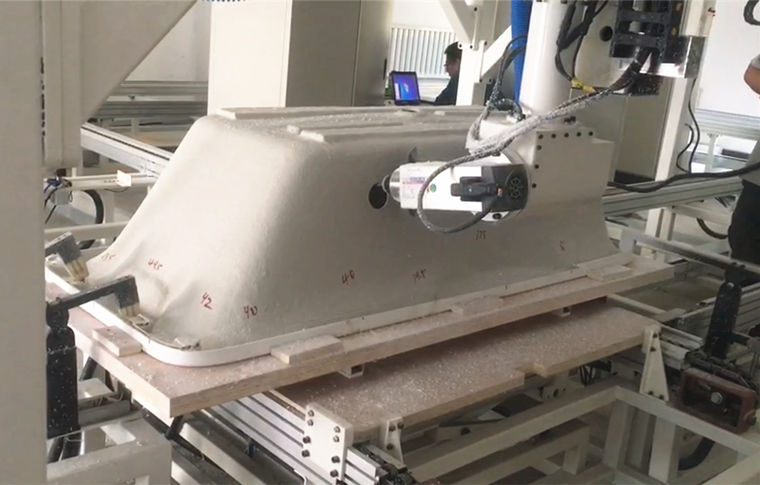

This article introduces an automated equipment designed and produced by Trumen for use in the bathroom industry - the automatic drilling robot for bathtubs.

Functional description of robotic arm

In the production of bathtubs in the bathroom industry, traditional manual drilling and milling operations result in high dust levels, poor working environments, and low efficiency. The automatic drilling robot designed by Trumen Company can help customers solve the problem of drilling multiple sizes of bathtubs. The holes opened are smooth and crack free, with clean edges, no stains, no bumps, and no corner drops. It is safe, efficient, easy to operate, and cost-effective.

The 3 # stop mechanism falls down, and the mold and bathtub are transported to the drilling processing position. The 2 # product recognition system identifies the bathtub specifications and placement position.

The drilling positioning cylinder starts, the truss robotic arm automatically starts drilling, and the dust collector starts.

The 3 # lifting and material transfer mechanism is activated, and the bathtub and mold are transported to the 4 # lifting and material transfer mechanism

Overall plan and layout

The overall plan consists of a six axis truss robotic arm, an industrial camera that automatically recognizes the size of the bathtub, and a dust removal system.

The above is an introduction to the automatic drilling robot arm. This equipment has flexible movements, multiple degrees of freedom, no dead corners, and accurate control accuracy.